- Starter Solenoid Switches

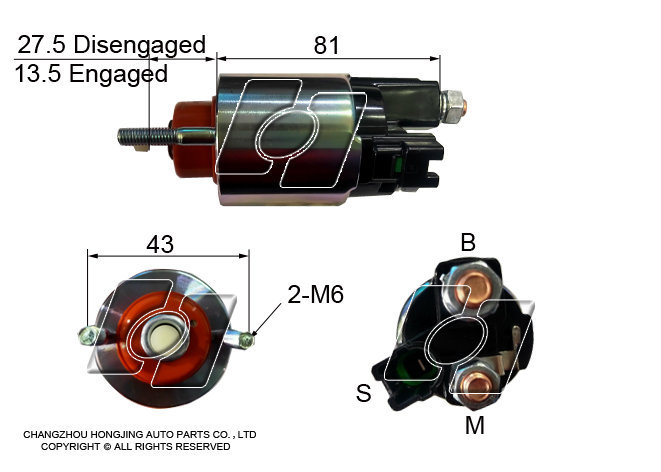

- BOSCH SYSTEM

- CONTINUOUS DUTY/PRESTOLITE SYSTEM

- CHRYSLER/PRESTOLITE SYSTEM

- DELCO SYSTEM

- FORD SYSTEM

- HARLEY DAVIDSON SYSTEM

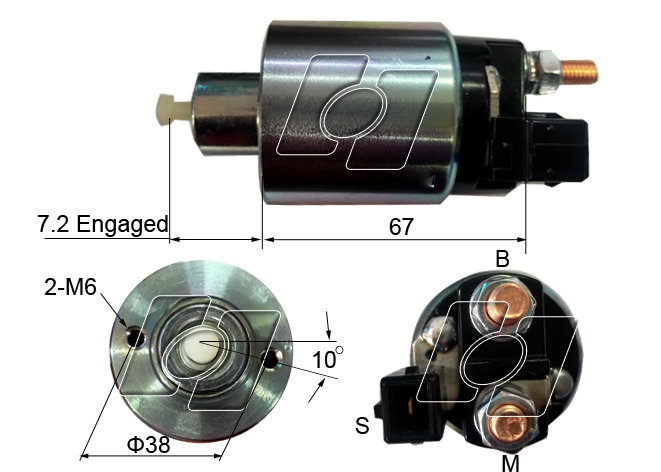

- HITACHI SYSTEM

- LUCAS SYSTEM

- MARELLI SYSTEM

- MANDO SYSTEM

- MECH. SWITCHES/MISCELLANEOUS SYSTEM

- MITSUBA SYSTEM

- MITSUBISHI SYSTEM

- NIPPONDENSO SYSTEM

- NIKKO SYSTEM

- PRESTOLITE SYSTEM

- VALEO SYSTEM

- BOSCH SYSTEM

- Small Parts

- Slip Rings

- Starter Drives

- Frames

Welding method of automobile fuel tank

Car fuel tank in the long-term use of the process, often due to vehicle bumps or corrosion and crack leakage. In addition to small cracks, little force can be used solder or adhesive blockage, the general use of electrical welding repair. However, in the welding of such containers have been installed oil products, we must strictly abide by the operating procedures, strengthen safety precautions, otherwise there will be unimaginable consequences. It is important to note that the fuel tank must be welded after thorough cleaning, because the oil products (especially gasoline) penetration is very strong, such as casually clean, oil and gas molecules is difficult to remove. In the welding, the flame ignited the fuel tank in the remaining combustible mixture of gas, it will cause an explosion.

General gasoline tank commonly used cleaning methods are:

1. Remove the fuel, remove the fuel tank, and then to the fuel tank filled with half the box of water, the boiler steam from the pipe into the water into the tank, so that the fuel tank boiling water for about 1 hour, so that the glue and dirt floating On the surface and was washed away, so twice can be.

2. Clean the fuel tank with hot water and dry it with compressed air to remove its internal gasoline steam. Finally, add the fuel tank to an aqueous solution containing 10% sodium hydroxide. After washing with water rinse its internal and external, if found to have external corrosion, brush with a net wire.

3. If you do not have the above conditions, you can also rinse the fuel tank with water. Method is to insert the water pipe into the tank mouth, open the oil drain bolt and float mouth, with water pressure continuous washing for 5 days or so, until the smell of gasoline can not be welded before welding. After cleaning the good fuel tank, then check its seal. Method is: first the fuel tank of the hole with rubber stopper blocked, and then immersed in water, the pressure of 117.6 ~ 147kPa compressed air from the tank pipe joints into the tank, the air is the location of the leak. The paint will be scraping the net, if the loopholes are not available soldering, loopholes are too large application patch for welding. When applying gas welding, fill in the fuel tank with cold water to prevent explosion. After welding with a knife frustration welding place, and then check the high pressure air seal of the fuel tank, and then welded and then loaded with the use. This will ensure the safety of the production, but also to ensure the quality of gasoline tank welding.

4. Car electrical welder workplace, must be kept dry, clean, with good ventilation and natural light (or lighting), the area shall not be less than 4 square meters; the walls and the surrounding should be free of flammable and explosive materials, so as to reduce the workers Fatigue, improve labor efficiency, and ensure safe production. Welding should pay attention to the risk of fire, molten metal spatter and hot welding head are likely to fall to the combustible material and cause combustion. In the car on the local repair, the first should be removed or isolated gasoline tank, so that Mars will be detonated fuel accident.

5. In order to prevent the risk of electric shock, automotive electrical welders in the operation to be protected. Wear dry and clean work clothes and insulated shoes; in the dry place to work the welding hood and welding parts must be grounded; welding equipment repair must be cut off the power switch; cable and welding clamp handle should be a good insulation, cable and welding The connecting bolts of the equipment shall be tightened to tighten the equipment; the first line of the demolition or repair of the welding equipment shall be carried out by a professional electrician and shall not be free to fiddle with it.

6. Arc emitting harmful to the human body Infrared, ultraviolet and intense light. People's eyes are exposed to infrared radiation for too long, will cause "crystal body" eye disease, severe cases will be blind. UV even a short exposure will cause "photophobia" eye disease, which caused pain and tears. UV rays can also cause skin burns, even peeling. Strong visible light exposure to a short time will make people eye flowers, too long will cause vision loss. In addition, in the arc welding may also be melting metal spatter burns. To this end, the electric welder in operation before, in addition to wear uniforms and insulation shoes, but also must be required to wear special leather gloves, wear special special care glass or a mask or mask. As an electrical welder must understand the importance of safe production, familiar with the safety protection knowledge, comply with operating procedures to ensure safety in production.

- 2017-05-24 > What are the accessories for the car starter?

- 2017-04-18 > Maintenance and maintenance of automobile hoses

- 2017-03-09 > Welding method of automobile fuel tank

- 2017-02-20 > Auto parts market frequency is "false foreign devils"

- 2017-02-03 > Nine automatic maintenance methods for auto parts

- 2017-01-17 > Auto auto industry pattern quietly changed